Product Description:

The Multilayer Zirconia Block is a cutting-edge dental material designed to meet the highest standards in dental restoration. Engineered with precision, this product features 8 distinct layers that replicate the natural gradient of tooth enamel and dentin, providing an exceptional aesthetic outcome. The multilayer configuration ensures a seamless transition of shades and translucency, making it an ideal choice for creating lifelike dental prosthetics that blend harmoniously with the patient’s natural teeth.

One of the standout characteristics of this multilayer zirconia disc is its remarkable sintering density of 6.0g/cm³. This high sintering density is indicative of the material’s superior compactness and structural integrity after the sintering process. Such density not only enhances the mechanical properties of the zirconia ceramic blocks but also contributes to their durability and longevity in clinical applications. The consistent density throughout the layers ensures uniform strength and stability, which are critical for the demanding environment of oral function.

Compatible with the Amann Girrbach system, the multilayer zirconia block offers seamless integration into existing dental CAD/CAM workflows. This compatibility facilitates precise milling and shaping, allowing dental technicians to produce restorations with exceptional accuracy and fit. The synergy between the material properties and the sophisticated Amann Girrbach system optimizes the fabrication process, reducing production time while maintaining high-quality outcomes.

In terms of mechanical performance, the zirconia dental ceramics incorporated in this product exhibit an impressive bending strength of 900 MPa. This high bending strength ensures that restorations made from these blocks can withstand the significant masticatory forces encountered in the oral cavity without fracturing or chipping. Consequently, dentists and technicians can confidently use these zirconia ceramic blocks for a broad range of restorations, including crowns, bridges, inlays, onlays, and implant-supported prostheses.

The density of the multilayer zirconia disc ranges between 6.0 and 6.3g/cm³, reflecting slight variations that can occur during manufacturing, yet always maintaining optimal material quality. This density range contributes to the material's robustness and resistance to wear, crucial factors for long-term clinical success. The high density is also associated with excellent biocompatibility, making these zirconia dental ceramics safe for patient use with minimal risk of adverse reactions.

Beyond strength and aesthetics, the multilayer zirconia block offers excellent translucency and color stability, essential for achieving natural-looking restorations. The multiple layers are carefully engineered to mimic the optical properties of natural teeth, providing depth and vitality to the final prosthesis. This feature is particularly valuable in anterior restorations where aesthetics are paramount.

In summary, these multilayer zirconia ceramic blocks represent a state-of-the-art solution for dental professionals seeking to deliver durable, aesthetic, and biocompatible restorations. With 8 well-defined layers, a sintering density of 6.0g/cm³, compatibility with the Amann Girrbach system, a bending strength of 900 MPa, and a density range of 6.0-6.3g/cm³, this product stands at the forefront of zirconia dental ceramics technology. It offers a perfect balance of mechanical performance and aesthetic appeal, ensuring patient satisfaction and clinical success in a variety of restorative applications.

Technical Parameters:

|

System

|

Amann Girrbach

|

|

Origin

|

China Manufacturer

|

|

Layers

|

8 Layers

|

|

Sintering Program

|

1500 Degree

|

|

Compatible Machines

|

Roland/VHF/Imes-icore

|

|

Density

|

6.0-6.3g/cm³

|

|

Type

|

Pre Shaded Zirconia Blocks

|

|

Colors

|

A1-D4

|

|

Bending Strength

|

900 MPa

|

|

Chemical Solubility

|

<100 μg/cm²

|

Applications:

The world's first eight-layer multilayer zirconia offers seamless layering that enhances aesthetic appeal to an exceptional level. This innovative material has been carefully designed to support the fabrication of 14-unit bridges, consistently achieving outstanding success rates.

This remarkable zirconia gradually changes in several key properties, including strength, color, translucency, and hardness, moving smoothly from the cervical area to the incisal edges. Such progressive transitions ensure a natural and lifelike appearance.

As a pioneer in the field of multilayer zirconia, this product features eight distinct layers and fifteen subtle gradient shifts. This unique combination provides unparalleled beauty and long-lasting durability, setting a new standard in dental materials.

Support and Services:

Our Multilayer Zirconia Block is designed to provide exceptional strength and esthetics for dental restorations. For optimal results, it is recommended to follow the specific milling, sintering, and glazing instructions provided with the product.

When milling the block, ensure that the milling machine is calibrated correctly and that appropriate burs are used to prevent chipping or cracking. After milling, the restoration must be carefully cleaned before sintering.

Sinter the restoration in a high-temperature furnace according to the specified temperature and duration outlined in the product guidelines. Proper sintering is crucial to achieve the desired mechanical properties and translucency.

Once sintered, the restoration can be stained and glazed to match the patient’s natural dentition. Use only compatible stains and glazing materials recommended for zirconia to ensure durability and esthetic integration.

For any technical support or troubleshooting related to the Multilayer Zirconia Block, please refer to the detailed user manual provided or visit our online resource center for FAQs, instructional videos, and software updates.

Regular maintenance of milling equipment and furnaces is essential to maintain the quality of your restorations. We also recommend periodic training sessions for technicians to stay updated with the latest techniques and product improvements.

Packing and Shipping:

Product Packaging and Shipping for Multilayer Zirconia Block

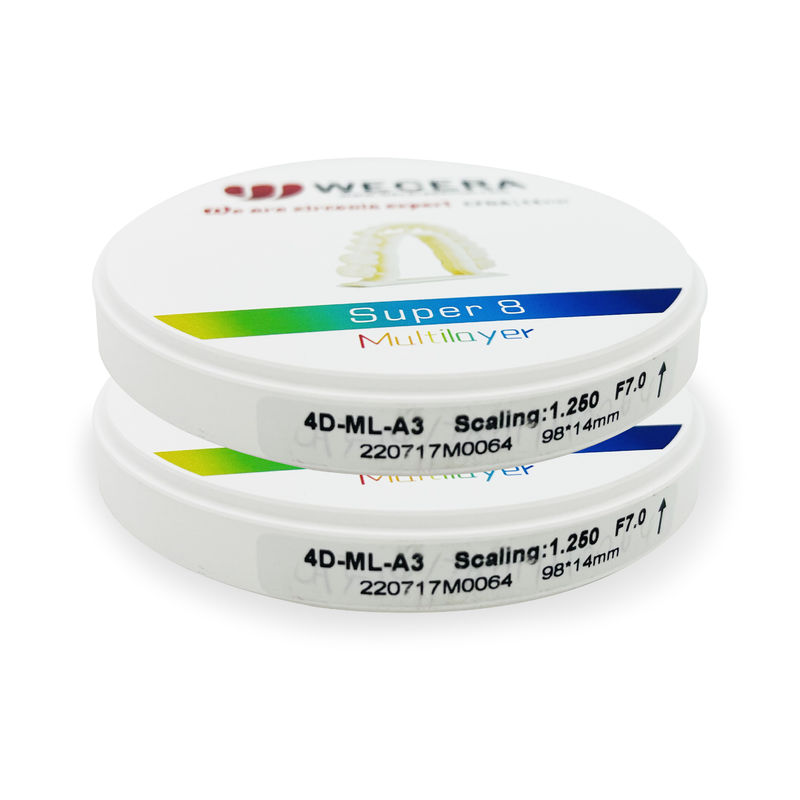

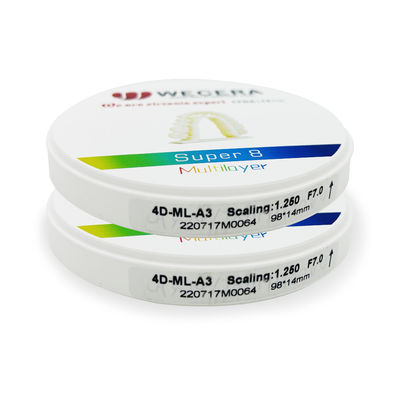

Each multilayer zirconia block is carefully packaged to ensure maximum protection during transit. The blocks are placed in individual protective sleeves, which are then securely housed within a sturdy, cushioned box to prevent any damage from shocks or vibrations.

The packaging materials are designed to maintain the integrity and cleanliness of the zirconia blocks, protecting them from dust, moisture, and contamination.

For shipping, we use reliable carriers with tracking options to ensure timely and safe delivery. The packages are clearly labeled with handling instructions and product details to facilitate smooth customs clearance and proper handling.

We also offer customized packaging solutions and expedited shipping options to meet specific customer requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!